The data centre sector rigidly employs established solutions, but innovation in ways of powering small urban data centres on a low environmental impactful gas is now being tested. RISE has been trialling high temperature fuel cells in a proof-of-concept demonstrator.

You may remember from your science teacher or from another equally sound source that hydrogen (as a gas) is the most abundant molecule in the universe and yet we have not managed to transition from a carbon-based energy system to that of hydrogen. There are some practical reasons for this, but first let us look at some interesting facts.

How do we obtain hydrogen? Hydrogen does occur naturally on earth (white hydrogen), but nowhere near in sufficient quantities to support the energy transition. Hydrogen can be manufactured from natural gas (methane) that produces carbon emissions (grey hydrogen) or where the carbon dioxide is captured and stored (blue hydrogen), but these two approaches are evidently carbon intensive.

It can be created by a process of electrolysis – using an electric current to separate oxygen and hydrogen from water molecules. The electrolysis process can produce 1 kg of hydrogen from 9 kg of water with 39.4 kWh of electricity (assuming that the electrolysis cells are 100% efficient) and 1 kg of hydrogen has an energy value of 33.3 kWh. By comparison, natural gas has 13.9 kWh per kg.

However, the real issue for use is not mass, but volume – and this is where hydrogen does less favourably, with around 30% of the energy per unit volume compared to natural gas, and therefore there are issues of storage and transportation. Of course, the electrolysis process requires electricity and for green hydrogen this electricity must be from a renewable source.

With hydrogen, it is then possible to construct a system that reverses the electrolysis and produces electricity. This is achieved with fuel cells; they operate on the same (electrochemical) principles as batteries but use a continuous flow of (hydrogen) fuel.

A closer look at fuel cells

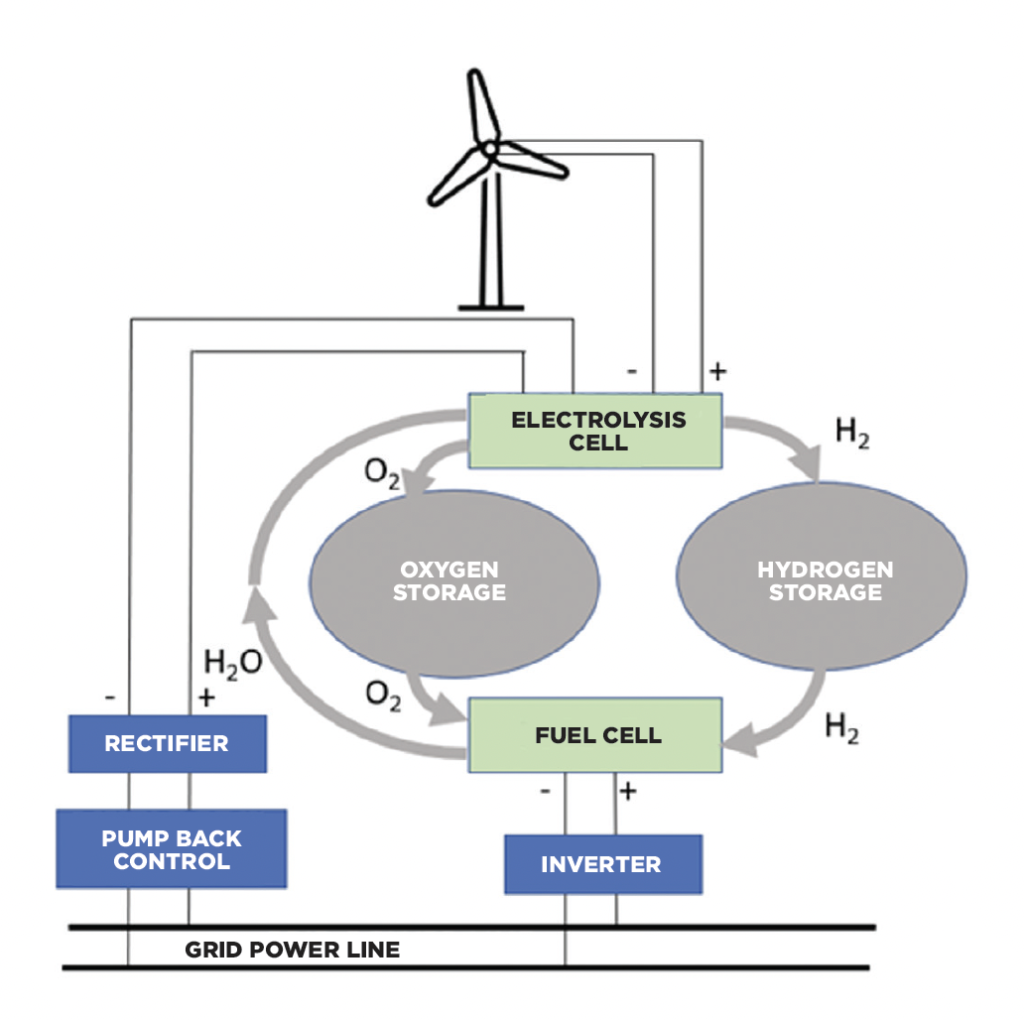

The fuel cell is an old technology, originally demonstrated in 1836 and known as gas batteries. Unlike power generation based on gas turbines, fuel cells produce direct current and do not combust the gas, and therefore they operate very quietly. A schematic was shown in the 1971 volume 225(3) of Scientific American within an article entitled The conversion of energy (redrawn in Figure 1) where a wind generator drives electrolysis cells to split the hydrogen and oxygen and store the gases for later use.

The schematic shows the use through fuel cells to produce electricity that is transferred to the electrical grid with inverters. The water is circulated as it is a by-product of the fuel cells to be used again in the electrolysis cells. Clearly, energy overproduction from renewables can therefore be stored as hydrogen at 33.3 kWh/kg.

Silent, low emissions, low grid power requirements and producing direct current are all attributes that could support small urban data centres. While the supply of hydrogen is one of the major practical challenges, there is a type of fuel cell that can run on many types of carbon-based fuels, biomethane or biogas being one of them. Such fuel cells are called solid oxide fuel cells (SOFC). If the biogas is produced locally from organic waste or wastewater that would otherwise emit methane into the atmosphere, then employing the gas to produce electricity for an urban data centre with the help of SOFC makes sense.

In practice

At RISE in Lulea, an EU H2020 funded project currently operates a small data centre using commercially available SOFC units (from SolydEra) running on locally manufactured biogas. The SOFC units operate at high internal temperatures (around 700°C) and provide electricity with an average of 55% efficiency (electrical energy as a ratio of the biogas energy value) with another 20% of the biogas energy being converted into thermal energy, with a temperature rise across the SOFC units of 20°C when connected to the heating network of the building that raises the return water loop to 65°C.

Figure 2 shows the nine SOFC units providing a maximum of 13.5 kW of electrical power lined up in a 20-foot ISO container. The demonstration produces alternating current via an inverter in each SOFC unit and hydrogen is internally produced from the biogas which has a carbon impact that would be the same as combusting the biogas, however with greater electrical efficiency.

Commercial SOFC units are not easy to acquire – there are many prototypes or laboratory produced units which is indicative of the TRL of the technology. However, RISE in Lulea is also coordinating another project that receives funding jointly from the EU H2020 and the Clean Hydrogen Partnership, where a more (> 650%) power dense SOFC system is being manufactured to provide 90 kW of prime power from natural gas with UPS integration and no power conversion.

A data centre demonstrator will operate for a year with a mixture of natural gas and hydrogen to determine electrical efficiencies and full operational understanding. The important fact to note is that when using SOFC systems, the high temperatures of operation mean that these units are not thermally cycled – that is they need to operate continuously, which is why SOFC is for stationary applications, such as data centres.

In the future, the high temperature SOFC will operate on hydrogen as does the more commonly proton exchange membrane fuel cell (PEMFC), but with a higher electrical and thermal efficiency. But, since PEMFC systems operate at much lower temperatures, they can be used for mobile and backup power requirements. For data centre backup, there are still limitations versus the common gensets (that could operate with biodiesel) due to current PEMFC power densities and the need for stored hydrogen.

One last fact is that the SOFC can theoretically be used in reverse as a solid oxide electrolysis cell (SOEC) with an efficiency (energy value of the hydrogen as a ratio of the electrical energy) of around 80%. Therefore the stationary solid oxide fuel cell infrastructure of the future could potentially be switching between hydrogen storage or electrical generation.

To conclude, there are various lower environmental impact gases that could be used to power small urban data centres or other important infrastructure in urban areas where noise limitations and electrical power grid congestion are important, but also where there are potential consumers of the excess heat from high temperature fuel cells that essentially operate as micro combined heat and power units.